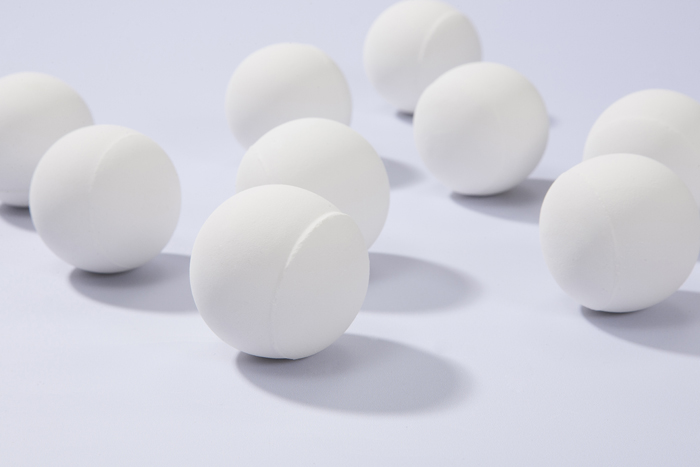

Alumina grinding ball is also known as high aluminum ball, alumina wear ball, inert alumina ball, it is now widely used in industrial grinding a very wide range of non-metallic grinding medium, through the use of calcined alumina after the unique wear resistance to grind powder or granular substances, widely used in different types of ceramics, enamel, glass, Chemical and other factories of thick hard material finishing and deep processing.

Alumina grinding ball because of its high strength, high hardness, high wear resistance, than the major, small size, high temperature resistance, corrosion resistance, non-polluting and other excellent characteristics gradually replaced the goose soft stone as the medium of grinding ball. In general, we will be according to the alumina content of different, alumina grinding ball into Chinalium ball, medium-high aluminum ball and high aluminum ball, in general, 60%-65% alumina content is classified as Chinalco sphere, 75%-80% alumina content is called medium-high aluminum ball, more than 90% alumina content of high aluminum ball,Alumina grinding ball has many advantages different from the metal grinding ball.

We all know that alumina grinding ball is high pure alumina powder after equal static pressure, high temperature sintering, but also because of the above characteristics, alumina grinding ball is widely used in a variety of industries in fine grinding, such as glass grinding, quartz grinding, cement grinding, lithium battery grinding and so on. In glass grinding, because of the hardness of glass is high, ordinary grinding medium processing capacity is limited, too much impurities mixed will reduce the quality of the glass, resulting in the quality of the glass is not good, can not make high-quality glass products. Alumina grinding ball can be a good solution to ordinary grinding medium can not solve the problem, can significantly improve the yield and quality of glass products. Cement grinding, is a very popular application in recent years, before most of the cement plant use more steel balls, with alumina ceramic grinding ball very low grinding, thermal conductivity, low density characteristics, in the two-stage grinding of cement has a good performance, energy saving and consumption reduction, improve product quality effect is obvious, gradually replace the steel ball. Grinding raw materials with alumina grinding ball can not only save electricity, improve production, but also improve the efficiency of mechanical use, and have a great protective effect on machinery and equipment.

Alumina grinding porcelain ball whether it is the development of industry and life, or from the environment and lifestyle progress, alumina grinding ball market has a good development prospects.